Categorization:Harness Component

In the pursuit of miniaturization and high performance in products such as smartphones, camera modules, medical probes, and wearable devices, extremely thin coaxial cables (Micro Coaxial Cable) have become the preferred solution for high-speed signal transmission and space utilization. They not only offer excellent electromagnetic shielding effects but also maintain flexibility and reliability within extremely small installation spaces. However, selecting a cable with matching performance is not an easy task—the wire diameter, impedance, shielding layer, and bend life are all factors that directly affect the final performance. Below, we will gradually analyze the key points for selecting extremely thin coaxial cables.

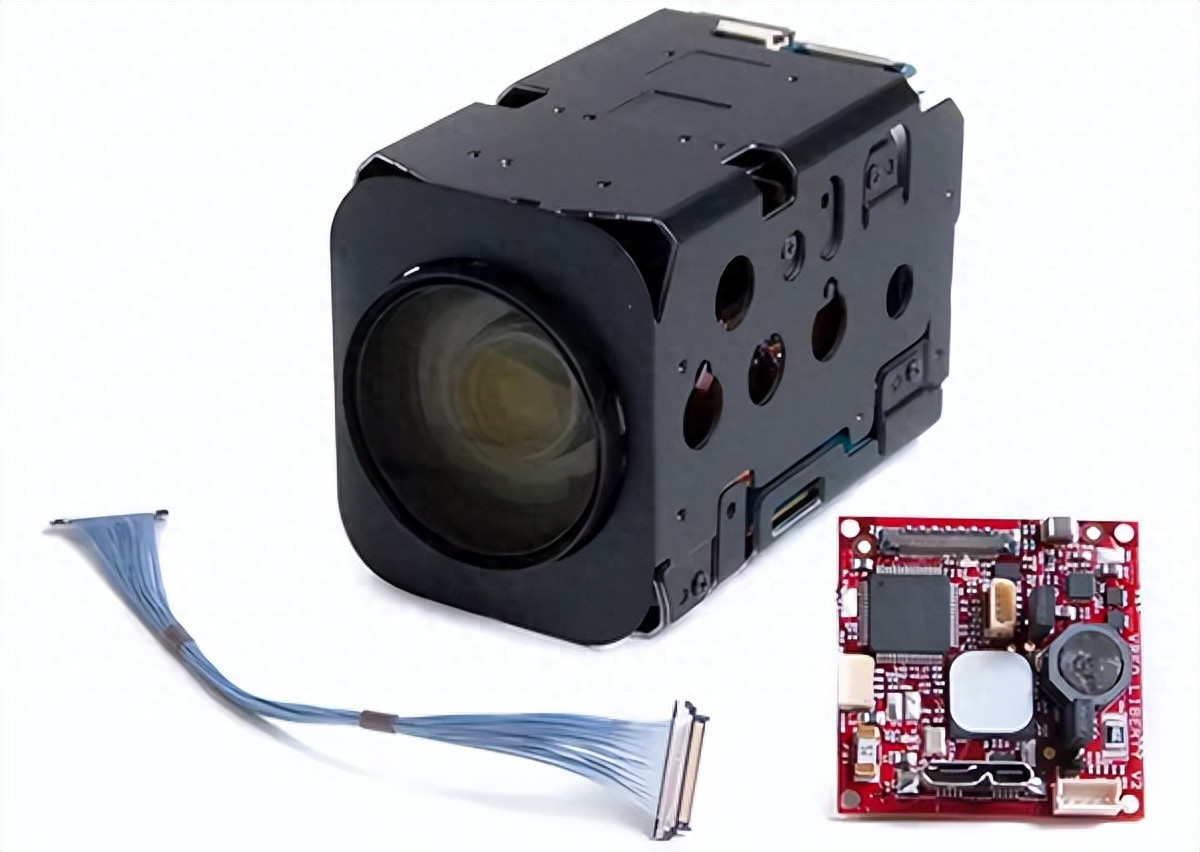

What is a super thin coaxial cable bundle?

The diameter of extremely thin coaxial cable bundles is usually around 1 millimeter, even thinner. The internal structure still follows the standard coaxial design: consisting of a central conductor, insulation layer, shielding layer, and outer sheath. Despite its small size, it can still ensure high-quality signal transmission performance, and is therefore widely used in fields with extremely high requirements for signal integrity, such as high-speed interfaces, radio frequency signals, ultrasonic detection, and image transmission.

Key parameters to focus on when selecting:

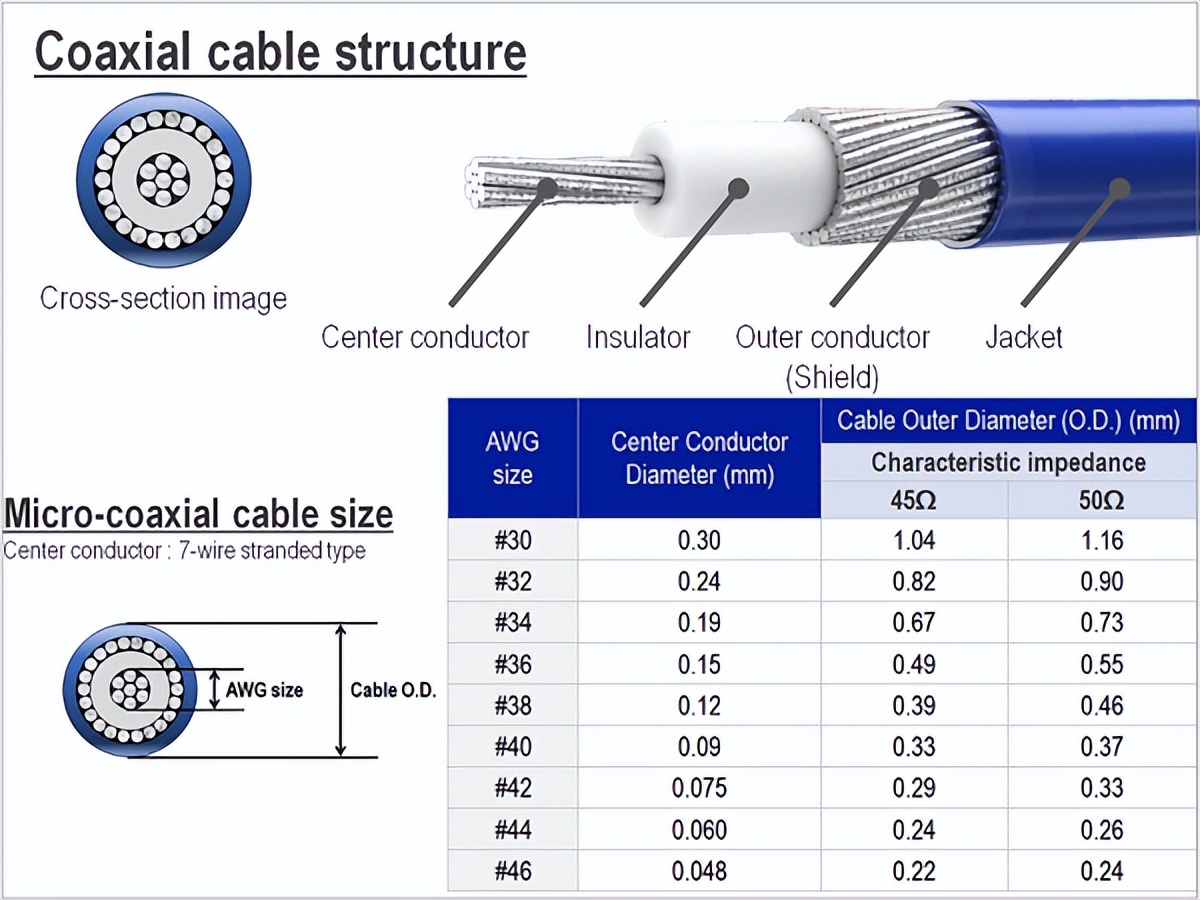

1. Wire diameter (AWG conductor size)

The thinner the conductor, the better the flexibility and the smaller the volume, but the resistance will also increase correspondingly. Common specifications include 38AWG, 40AWG, and 42AWG. If larger current transmission or longer distance signal transmission is required, a slightly thicker wire diameter should be chosen to reduce losses and impedance.

Impedance matching

Impedance mismatch can cause signal reflection and distortion. Common standards are 50Ω or 45Ω. In high-speed interfaces or RF applications, the system's impedance matching must be considered as a whole in the selection of wires, connectors, and PCB design.

3. Outside Diameter and Flexibility

The outer diameter size affects wiring space and bending performance. When designing, it is necessary to confirm the bending radius and bending life indicators to ensure the long-term reliable operation of the cable in dynamic structures.

4. Shielding performance

The coverage of the shielding layer is directly related to the anti-interference capability. For high-speed video transmission or medical ultrasonic applications, it is recommended to prioritize wires with perfect shielding structures and high density.

5. Material and Environmental Adaptability

The dielectric constant of the insulation layer affects the characteristics of high-frequency signals, while the material of the outer sheath determines its resistance to temperature, humidity, and chemicals. In medical, vehicle, or industrial environments, material stability and durability are particularly important.

Three, recommended selection process

1, Define application scenarios: confirm if it is for high-speed signal, radio frequency signal, or power transmission.

Determine basic parameters: Based on current and frequency requirements, preliminarily select wire diameter and impedance range.

3. Consider the installation environment: evaluate whether it requires frequent bending, and whether it operates in high-temperature or humid environments.

Sample verification: Test for performance to ensure it meets requirements through insertion loss, reflection, and bend lifetime, etc.

5. Balance trade-offs: find the optimal solution among performance, cost, and supply stability.

Four, Analysis of Common Misconceptions

1. Blind pursuit of finer wire diameter: Finer wire does not necessarily mean better; overly fine wire may cause significant signal loss and low mechanical strength.

Neglecting connector constraints: The spacing of the connector pins and the insertion and extraction life will affect the selection and matching of the wire harness.

3. Only looking at parameters without verification: Paper data may be good, but if it is not actually verified, it may cause signal attenuation or core breakage problems in application.

Selecting ultra-fine coaxial cable assemblies is a "balance art." To find the optimal solution among space constraints, frequency requirements, impedance matching, flexibility, and cost, a combination of experience, testing, and reasonable planning is needed. Only with a well-prepared preliminary design can the stability and reliability of the final product be ensured.

I am[Suzhou Huichengyuan Electronic], focused on the research and development, design and customization of high-speed signal cable harnesses and ultra-thin coaxial cable harnesses. We are committed to providing customers with high-stability high-speed interconnect solutions. If you have any related needs or want to learn more, please contact us:Manager Yin 18913280527 (WeChat number same)。