Categorization:Harness Component

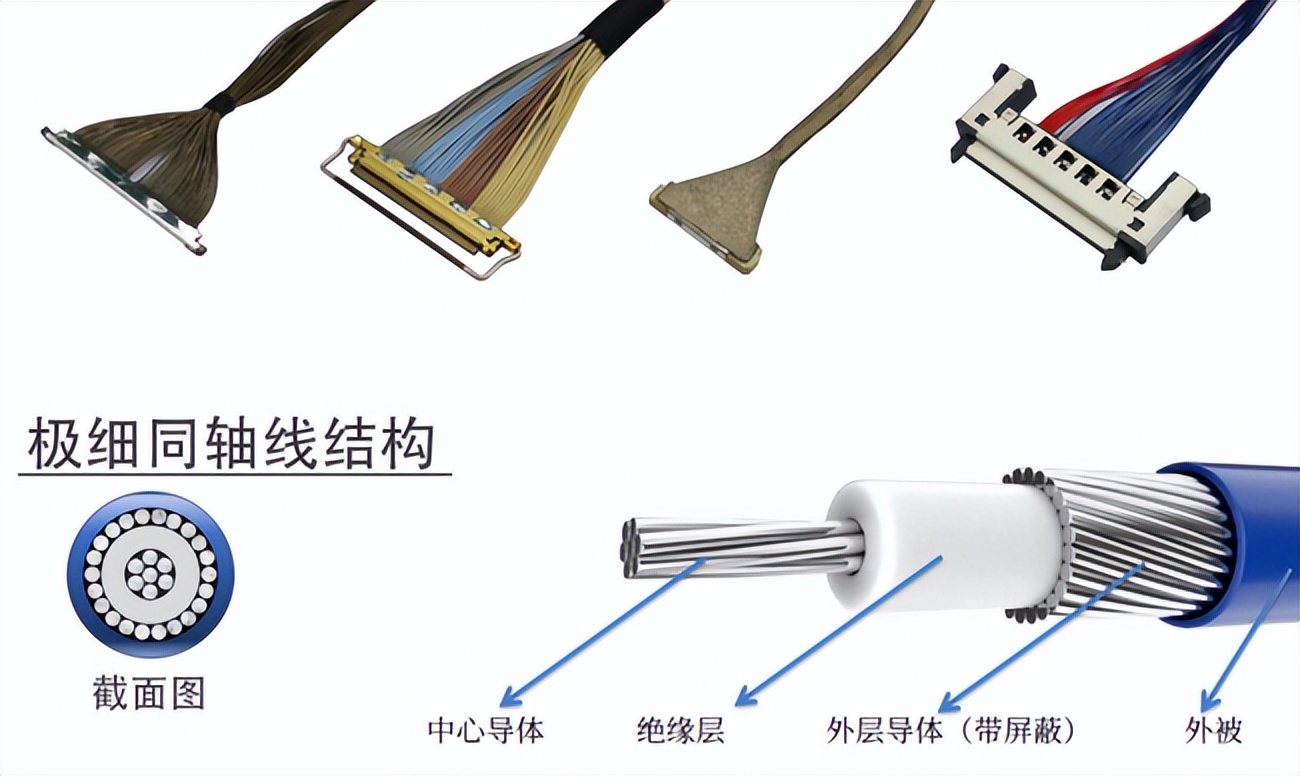

In the field of high-speed signal transmission, extremely thin coaxial cables (Micro Coaxial Cable) are widely used in medical imaging, consumer electronics, automotive electronics, and industrial equipment due to their lightweight, flexible, and excellent electrical properties. In order to ensure the integrity of high-speed differential signals, the design of the shielding structure becomes a critical link in determining performance.

The basic function of blocking.

The core function of the shielding layer is to suppress external electromagnetic interference (EMI) and reduce crosstalk between cables. For extremely thin coaxial cables with small diameters and dense arrangements, if the shielding is insufficient, high-frequency signals are prone to interference, leading to signal distortion or increased error rate. Therefore, the shielding design not only affects the transmission quality but also concerns the overall stability and reliability of the system.

Part Two: Common Shielding Structures

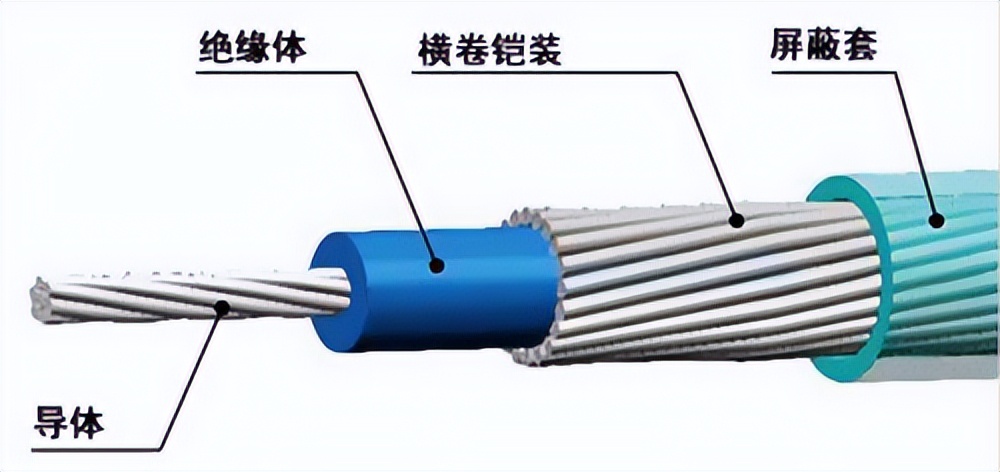

Single-layer woven shielding: Made of metal wire, with high coverage, suitable for medium and low frequency transmission scenarios.

(2) Copper foil + woven composite shielding: The copper foil layer provides nearly full coverage electromagnetic isolation, while the woven layer enhances mechanical strength and conductive properties.

(Multi-layer shielding structure: In high-speed transmission systems such as MIPI, LVDS, and USB4, multi-layer shielding can effectively resist complex electromagnetic environmental interference and ensure high signal integrity.)

Section 3: Special Features of Ultra-Fine Coaxial Beam

The wire diameter of Micro coaxial cable is typically only 0.3mm to 0.5mm, which greatly tests the balance of the shielding design. Designers must ensure excellent electrical performance while also considering flexibility and processability. A shield layer that is too thick can limit bending performance, while one that is too thin may reduce anti-interference capability. Therefore, in aspects such as material selection (such as silver-plated copper wire), weaving density, and the combination technology of the shield layer and jacket, fine-tuning optimization must be carried out to achieve a balance between performance and flexibility.

Four, future development trends

As the bandwidth requirements for medical endoscopic modules, high-definition cameras, and flat-panel display equipment continue to grow, the shielding technology of ultra-fine coaxial cables is evolving towards the direction of "lightweighting and high-performance in parallel". New technologies such as novel nanoshielding films, high-density weaving, and ultra-thin metal coatings will further enhance the anti-interference capability while maintaining flexibility, providing a more stable signal guarantee for the next generation of high-speed transmission systems.

The shielding structure is one of the core links in the design of extremely fine coaxial cable bundles, directly determining the signal integrity and system reliability. Rational shielding design can not only significantly improve the transmission quality but also ensure the long-term stable operation of the equipment under complex electromagnetic environments.

We areSuzhou Huichengyuan Electronic TechnologyFocusing on the design and manufacturing of ultra-fine coaxial cable bundles and continuously sharing engineering experience and application cases of high-speed signal transmission. Welcome to follow and communicate, and explore more efficient interconnection solutions together. If you have relevant needs or wish to learn more, please contact us:Manager Yin 18913280527 (WeChat same number)。