Categorization:Harness Component

In the era of rapid development of information, the interconnection design inside the equipment is increasingly trending towards miniaturization and high density. Among them, "extremely thin coaxial cable" (micro coaxial cable) is widely used in smart devices, mobile terminals, communication modules, and precision medical instruments due to its thinness, flexibility, and high-frequency transmission capabilities. However, as the cable diameter decreases, the problem of signal transmission loss becomes more prominent. This article will analyze the causes of loss in extremely thin coaxial cables from multiple perspectives and discuss the feasible paths for engineering optimization.

An Analysis of the Main Loss Types in Ultra-Fine Coaxial Cable Assemblies

Insertion loss is the most direct manifestation of energy attenuation. When the signal is transmitted from the transmitting end through the cable to the receiving end, part of the energy is lost as heat due to the conductor resistance and medium loss. Because the conductors of extremely thin coaxial cables have a small cross-sectional area and a high transmission frequency, the signal skin effect is more significant, causing the energy to concentrate on the surface of the conductor, thereby increasing the loss.

Reflection loss is mainly caused by impedance mismatch. When the impedance of the cable, connector, or PCB interface is inconsistent, part of the signal is reflected back to the source end, causing energy waste and signal interference. Especially in extremely thin wire structures, higher processing accuracy is required, and any deviation may amplify the reflection effect.

In addition, the loss related to standing wave ratio (VSWR) should not be ignored. Impedance mismatch can cause standing waves, causing reflections to叠加 in the transmission path, thereby reducing transmission efficiency. By strictly controlling design accuracy and ensuring impedance consistency among components, such losses can be significantly reduced.

The influence of structural and material optimization on performance

The transmission performance of extremely thin coaxial cables depends on their geometric dimensions and material characteristics. The finer the conductor, the greater the resistance, and the corresponding loss increases. To balance size and performance, engineers typically use low dielectric loss materials such as high-performance PTFE or fluoropolymers to reduce energy attenuation caused by medium absorption. For example, in medical imaging equipment, ultra-thin coaxial cables with low-loss media can reduce signal attenuation by about 10% compared to traditional cables. In addition, the longer the cable, the more significant the loss, so it is advisable to shorten the transmission path and minimize unnecessary bends in system wiring.

Part three: Improvements brought by transmission path optimization

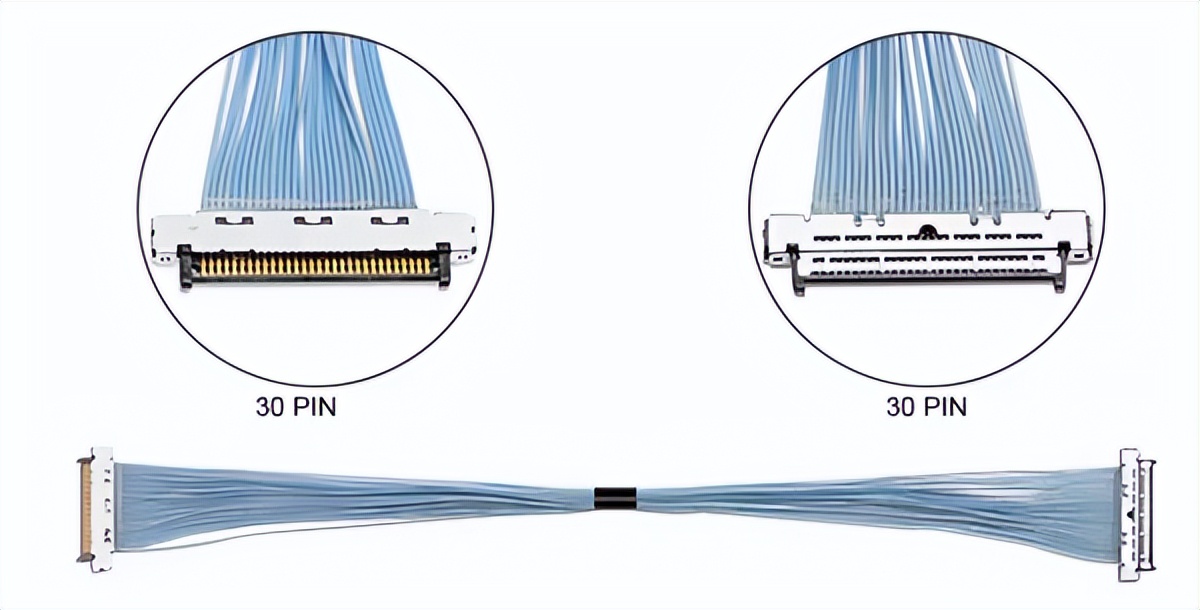

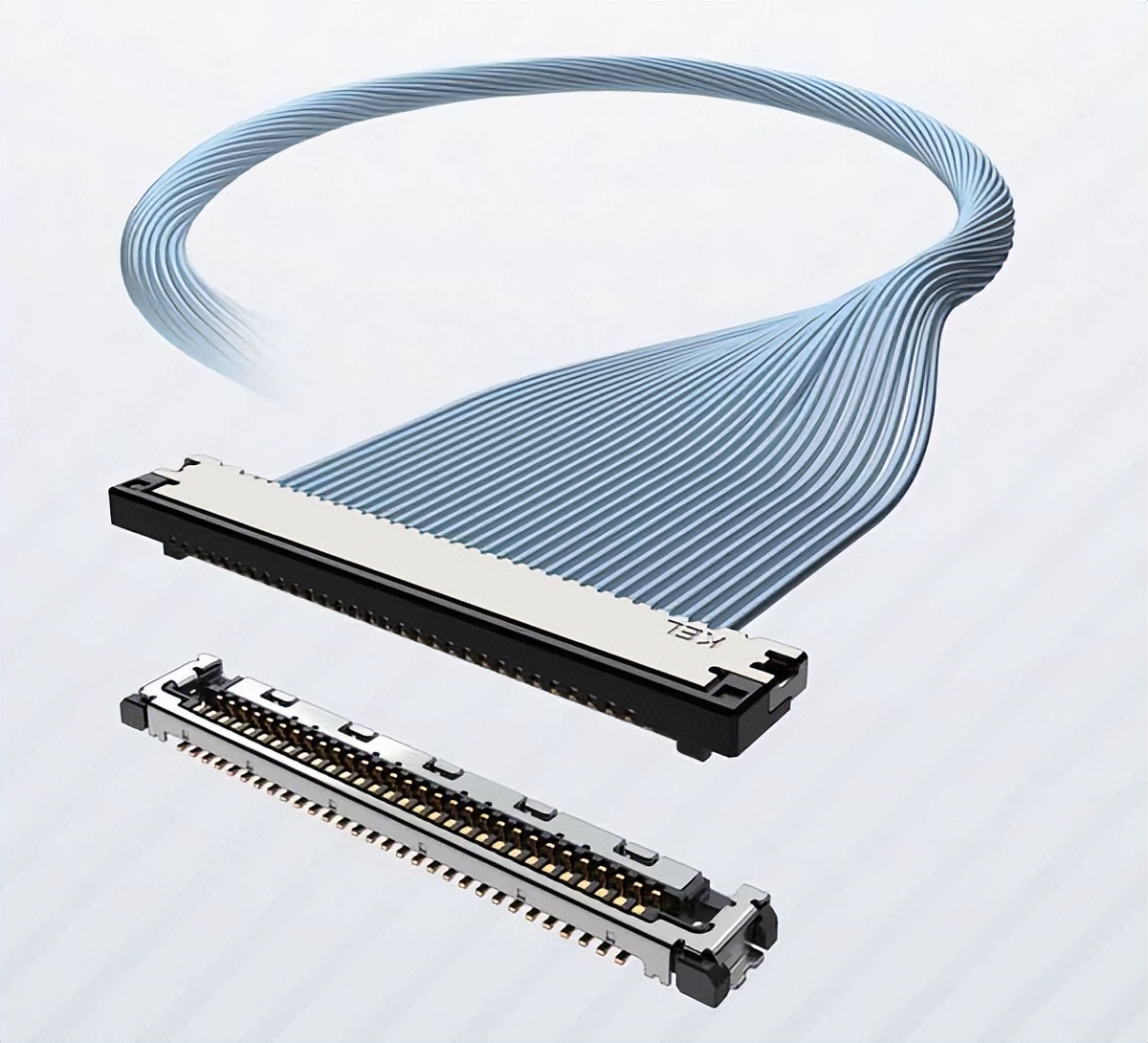

Under high-speed transmission scenarios, such as the proximity interconnection between chips and I/O modules, the traditional PCB trace (trace) loss is significant. By using extremely thin coaxial cables as jumpers (jumper harness), and pairing them with low-profile high-density connectors, the transmission path of high-frequency signals can be effectively shortened, reducing insertion and reflection losses. This solution performs particularly well in the 13-17GHz high-frequency range, significantly improving signal integrity (SI), and is therefore increasingly adopted by high-end devices.

Four, the influence of manufacturing technology and installation methods

Extremely thin coaxial cables are highly sensitive to process accuracy. If the stress distribution is uneven during bending or winding of the cable束, it can cause damage to the shielding layer structure or compression deformation of the medium, thereby increasing signal loss. During the production process, improper control of stripping, welding, or crimping techniques may also lead to impedance突变 or poor contact, triggering reflections and energy loss. Therefore, precision manufacturing equipment and automated assembly processes are crucial for ensuring signal quality. The signal loss of extremely fine coaxial cables is mainly affected by multiple factors such as conductor structure, medium material, impedance matching, processing accuracy, and installation methods. Through material optimization, precise design, accurate technology, and reasonable layout, signal attenuation can be effectively reduced, and the stability and reliability of the system transmission can be improved.

The signal loss of extremely fine coaxial cables is mainly affected by multiple factors such as conductor structure, medium material, impedance matching, processing accuracy, and installation methods. Through material optimization, precise design, accurate technology, and reasonable layout, signal attenuation can be effectively reduced, and the stability and reliability of the system transmission can be improved.

I amSuzhou Huichengyuan Electronics, Focus on the design and customization of high-speed cable harnesses and extremely thin coaxial cable harnesses for a long time, committed to providing customers with high-performance and reliable high-speed interconnection solutions. If you have related needs or want to learn more in depth, welcome to contact:Manager Yin 18913280527 (WeChat same number)。